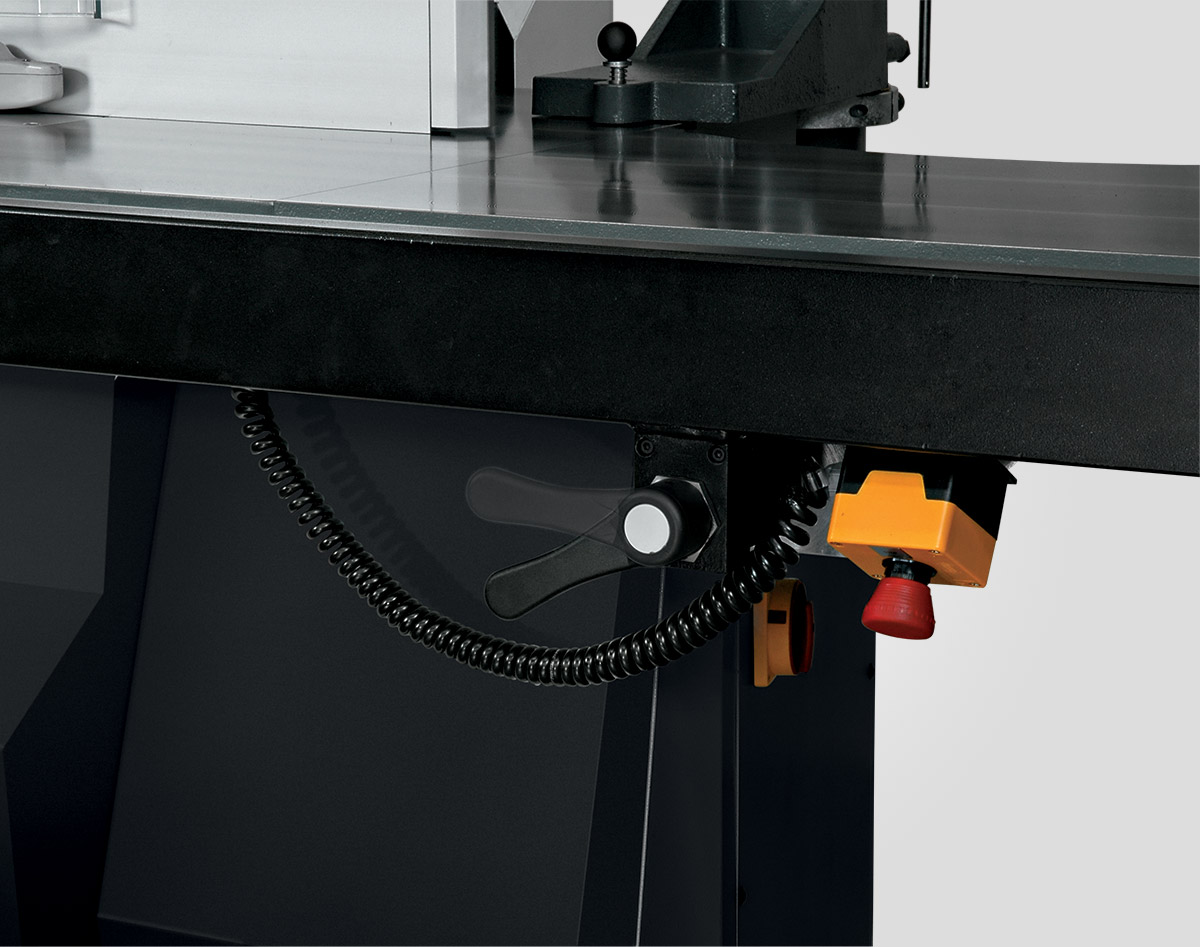

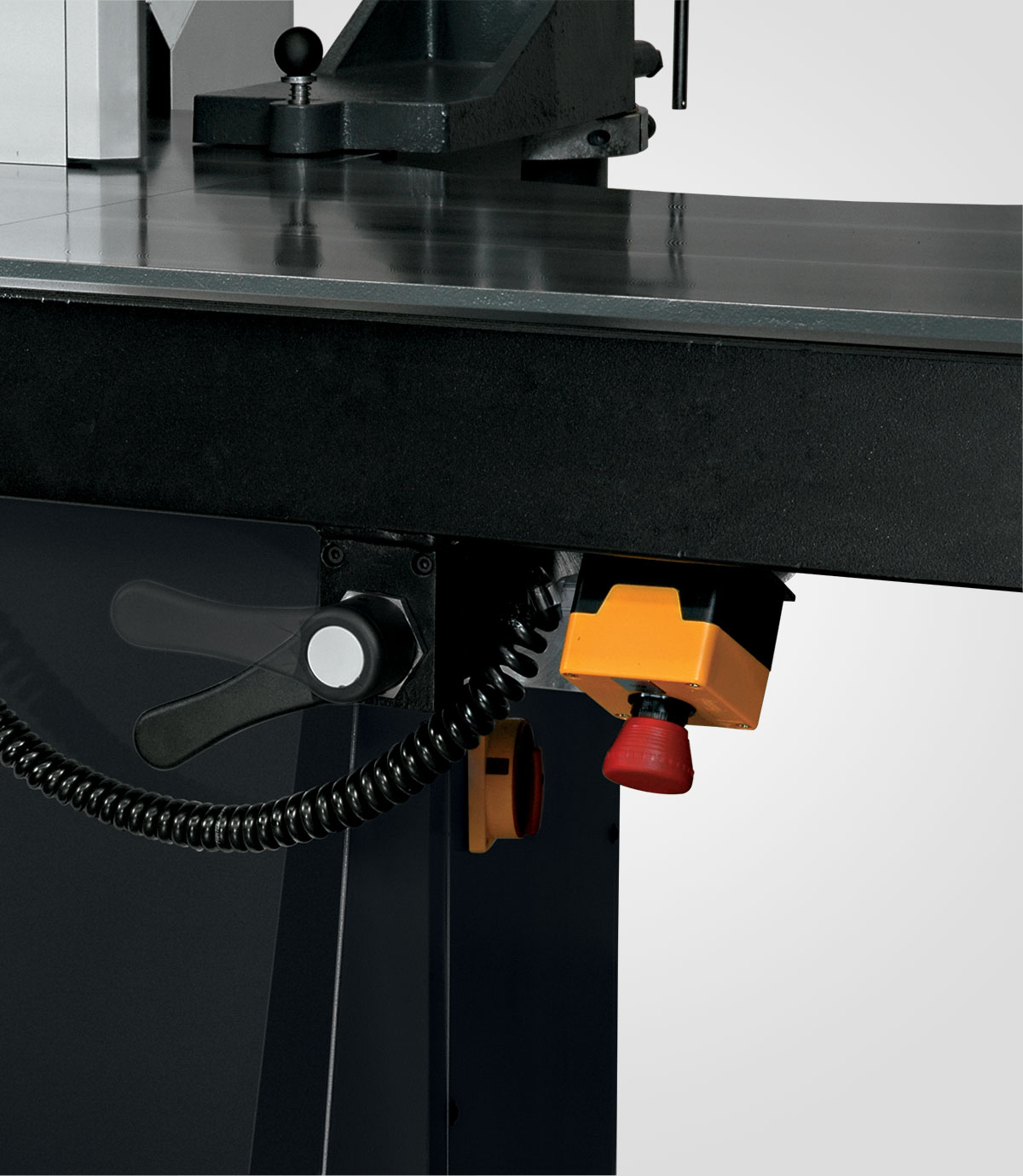

SECTIONED WORKING TABLE

The sectioned working table without the front encumbrance can be adjusted without using any tools by means of a patented hold that unlocks, locks and positions in the same time the sliding table even with the assembled tool, allowing then to get the max support for the workpiece.

SPINDLE MOULDER FENCE

The patented spindle moulder fence is equipped with 2 levers locking and unlocking it quickly by a 90° rotation, while the removing and quick positioning of the table fence takes place with motorized rotation and lifting.

The positions are checked by special sensors.

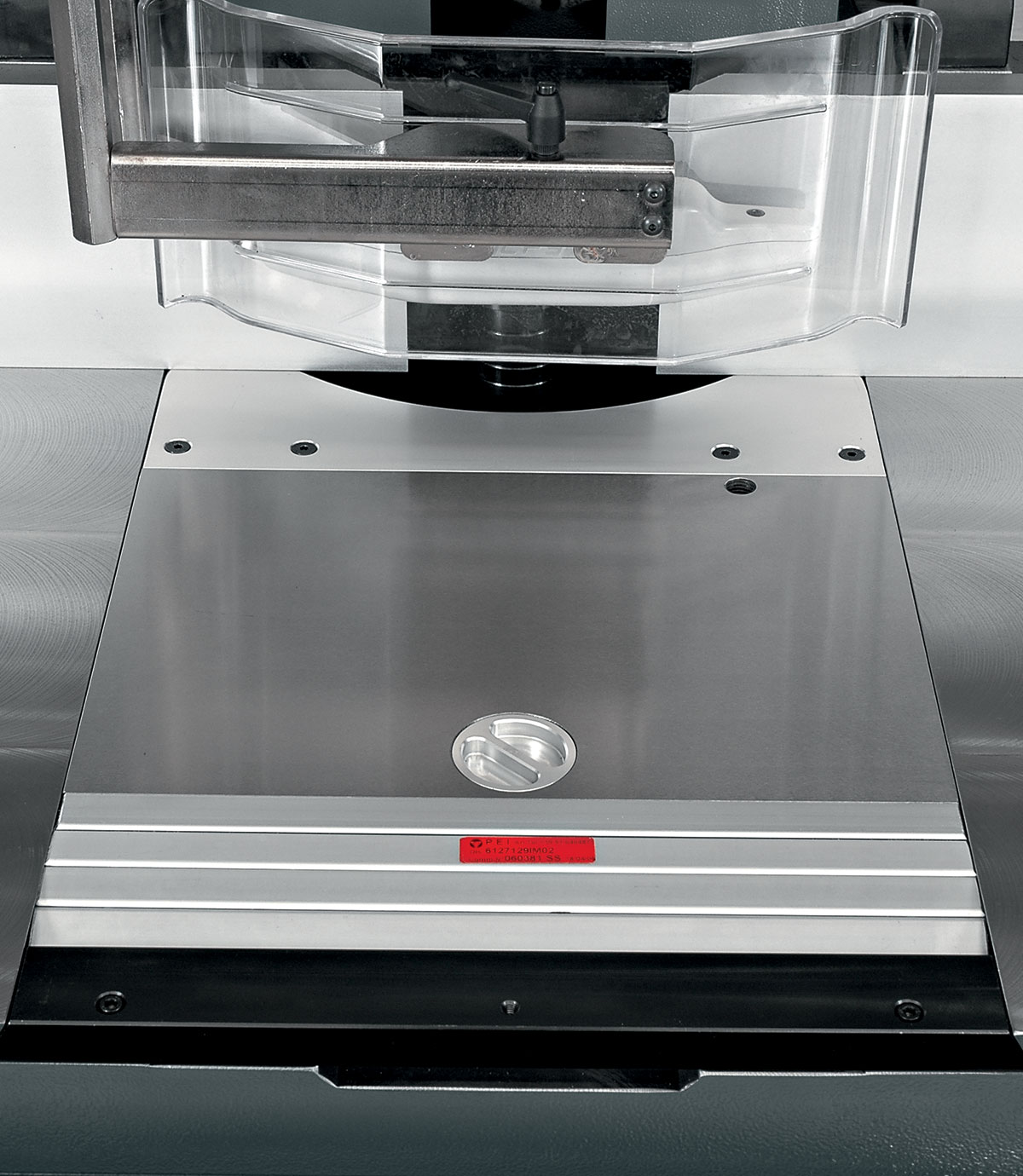

TABLE FRONT WIDENING

The table front widening has been simplyfied through the introduction of the sliding on tempered bars and balls sleeves, moreover, this operation has been quickened by mean of a handle allowing the unlocking, locking and translation at the same time (patented).

TECHNICAL DATA

ON REQUEST:

- Spindle moulder speed variator with inverter

- Automatic star-delta starting

- Increased motor power

- 2 cylinder pneumatic clamping arm

- 2 or 3 axes programmer

- Automatic feeder 6 rollers

- Reverse spindle rotation

- “Hermetic” aluminium plates

- Electric readout tool height

- Hanging control panel

- Upper glazing bead recovering unit

- Support for manual or motorised feeder