KR-SPIN ROTOMATIC

FIMAL TRANSFORMS THE HORIZONTAL BEAM SAW INTO AN AUTOMATIC SIZING CENTER

Horizontal Sizing Center for panels, developed to safisfy both serial production needs and one-off production (so called lotto one), without afflicting machine lead time.

Thanks to the innovative ROTOMATIC system, which automatically moves the stripe made with the first longitudinal cut to the cross-cut, productivity and accuracy of the finished workpiece do not depend on the operator anymore. The only task for the operator is to unload the finished workpieces from the machine.

Productivity

Flexibility

25% higher production capacity

40% less operator work

100% certainty of lead time

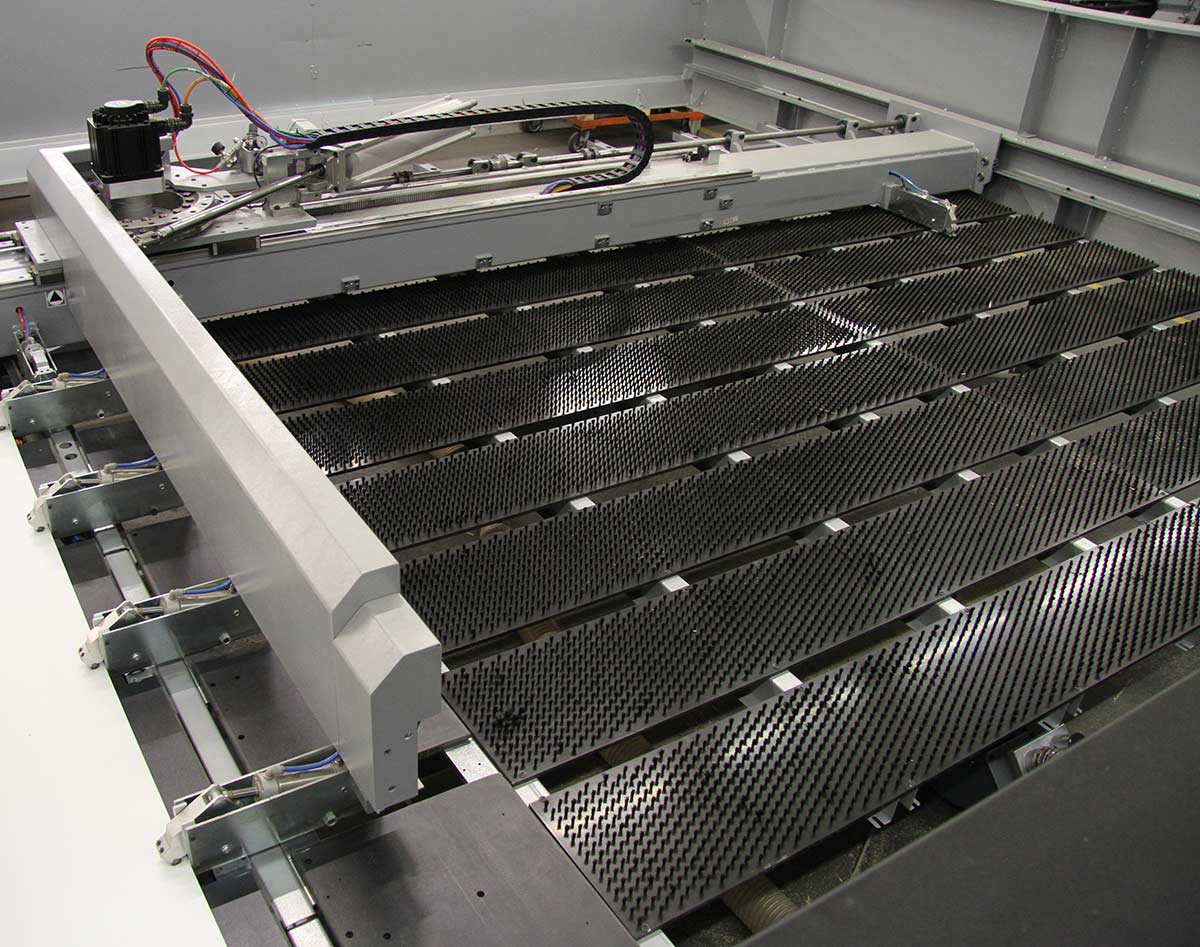

MAIN STRUCTURE

Machine Base made of tubular steel lattice-welded as unique body, wrought on NC metalworking machinery with only one positioning to guarantee high precision of each size and orthogonality of the surface.

Working table area made of steel with reinforcement spines, covered by anti-scratch bakelite as a safeguard for the panels during every working phase.

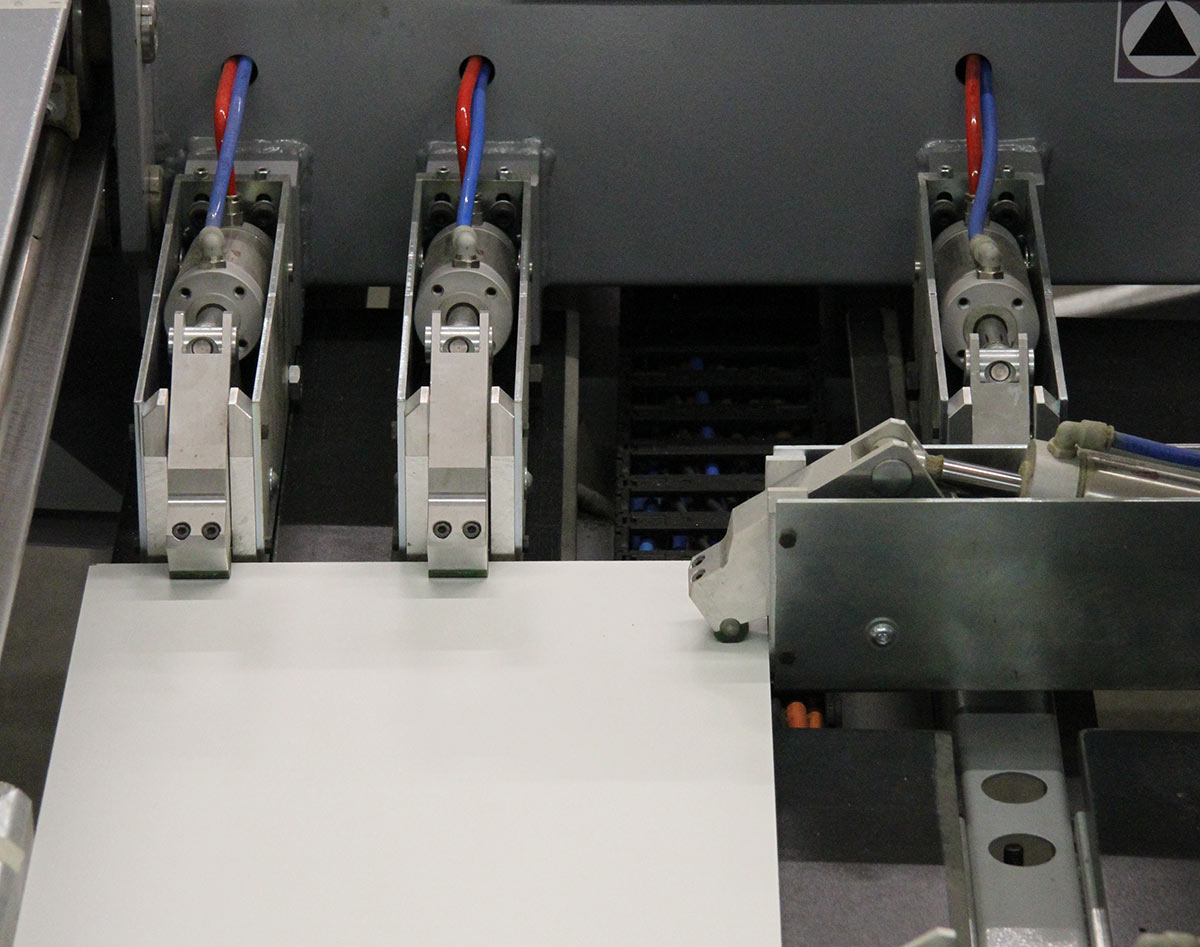

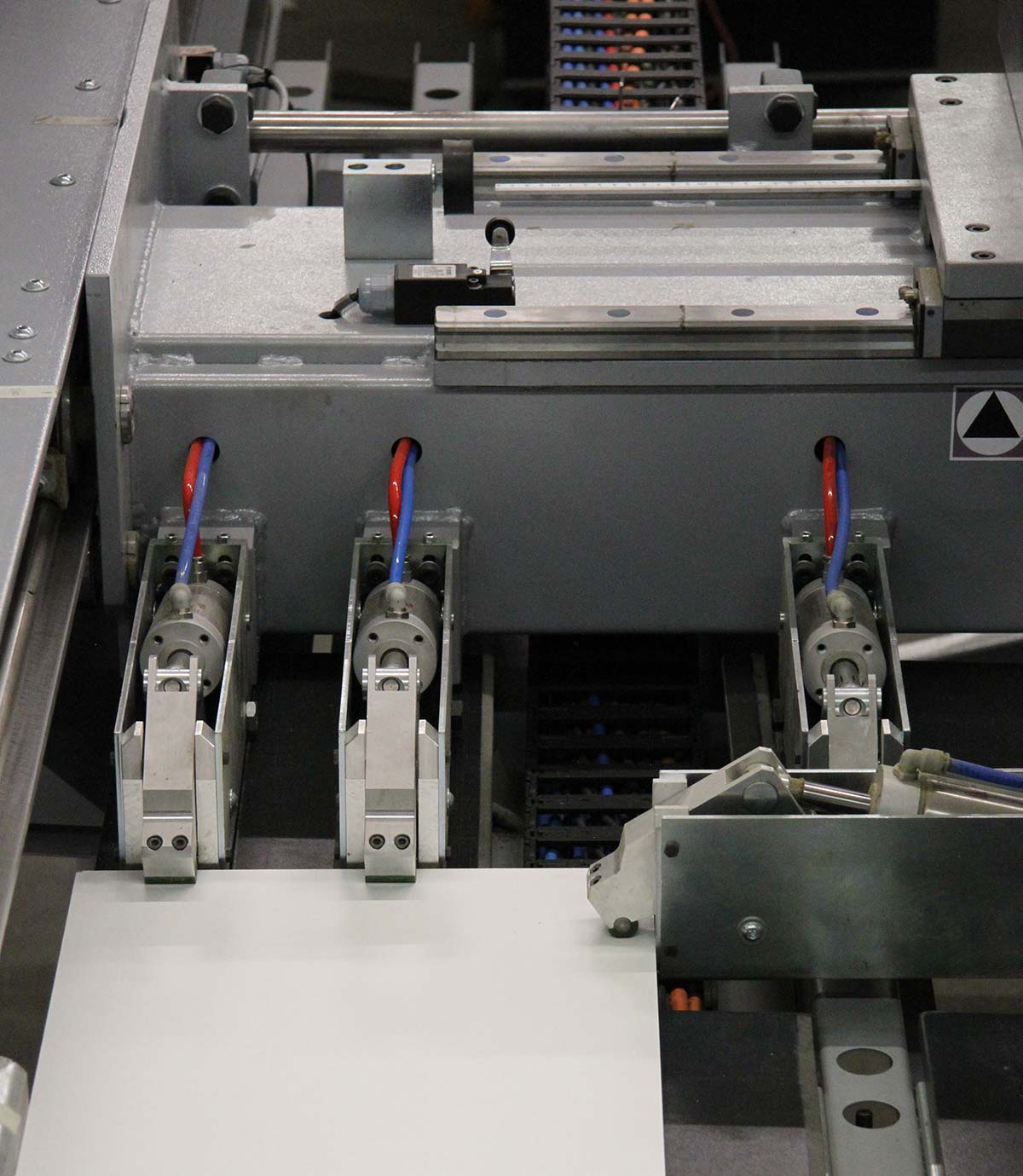

Two solid structure pressure beams with independent action to guarantee the strong holding of the panel back and front of the cutting line and strong holding of the stripe on the cross-cut side.

Moved pneumatically on bar guides, balanced by torsion bar and rack, with external pressure adjustment easily accessible.

Tilting curtain guards and emergency bar to avoid accidental collision with blades or crush.

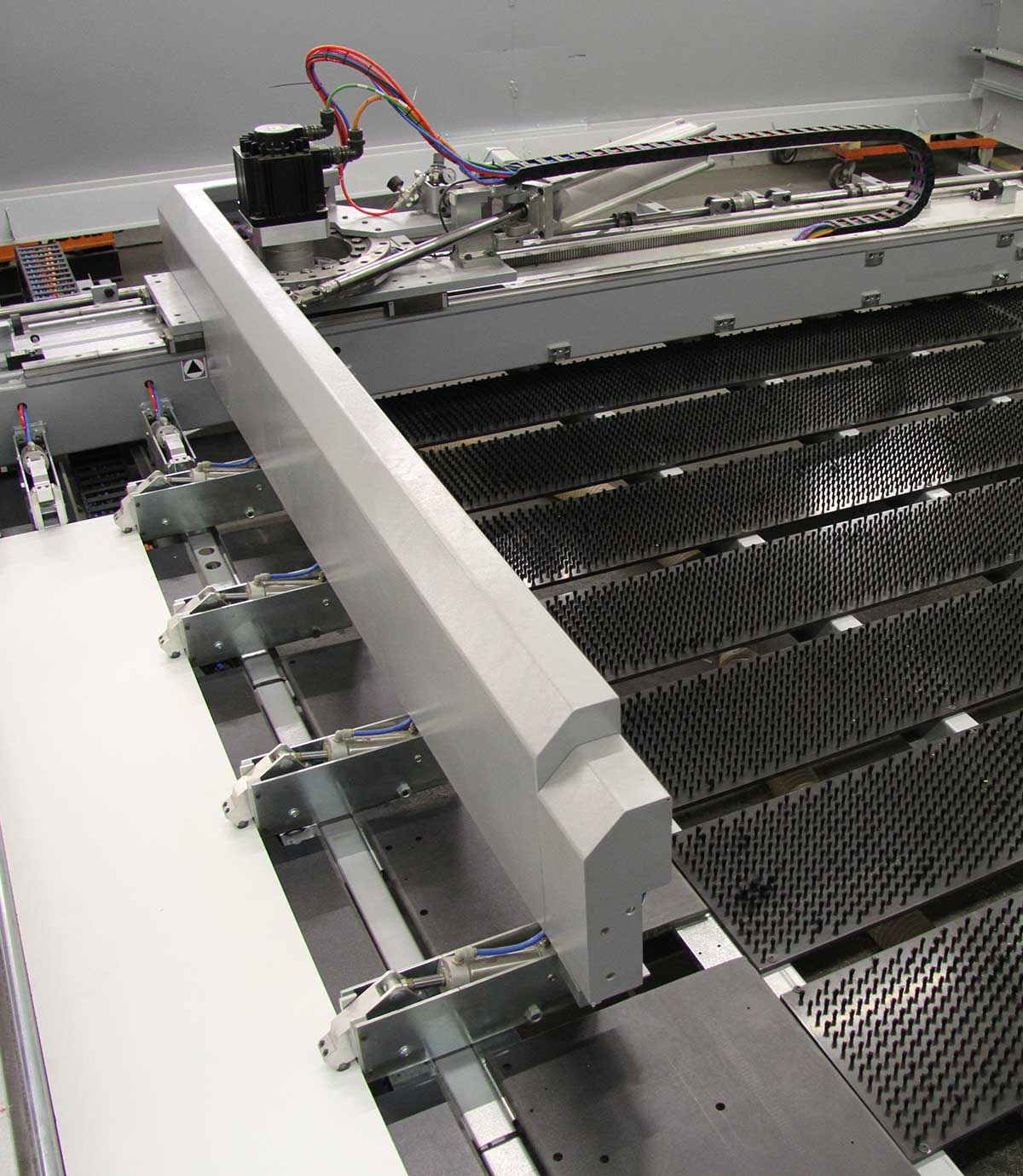

ROTOMATIC PUSHER

Pusher bar made of strong thick tubular structure to guarantee rigidity and accuracy, Brushless motor for the movement, torsion bar system and rack and pinion made of tempered rectified steel to guarantee the accuracy of positioning, movement on H-profile strong thick beams which give high precision and stability to the whole structure.

Provided with 8 clamps with possibility to adjust the clamping pressure. 4 of those clamps rotate through fifth-wheel located on the pusher itself (ROTOMATIC system) and translating on linear guides, recirculating ball slideways, moved by Brushless motor for the rotation of the stripe from the longitudinal cut area to the cross-cut area.

Support of the panel on the back side through brushes with double advantage in terms of safeguard of the panel surface and to help the rotation of small and big panels.

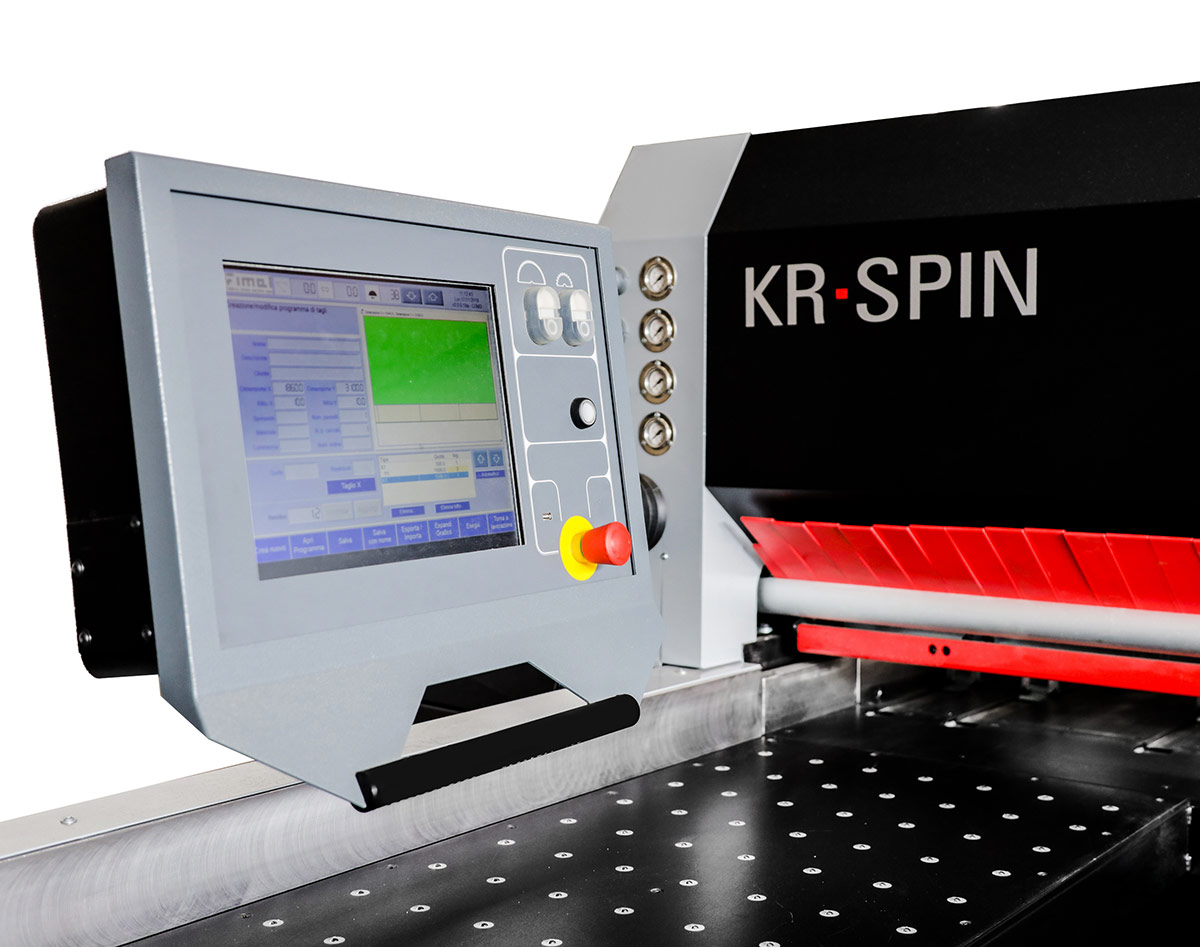

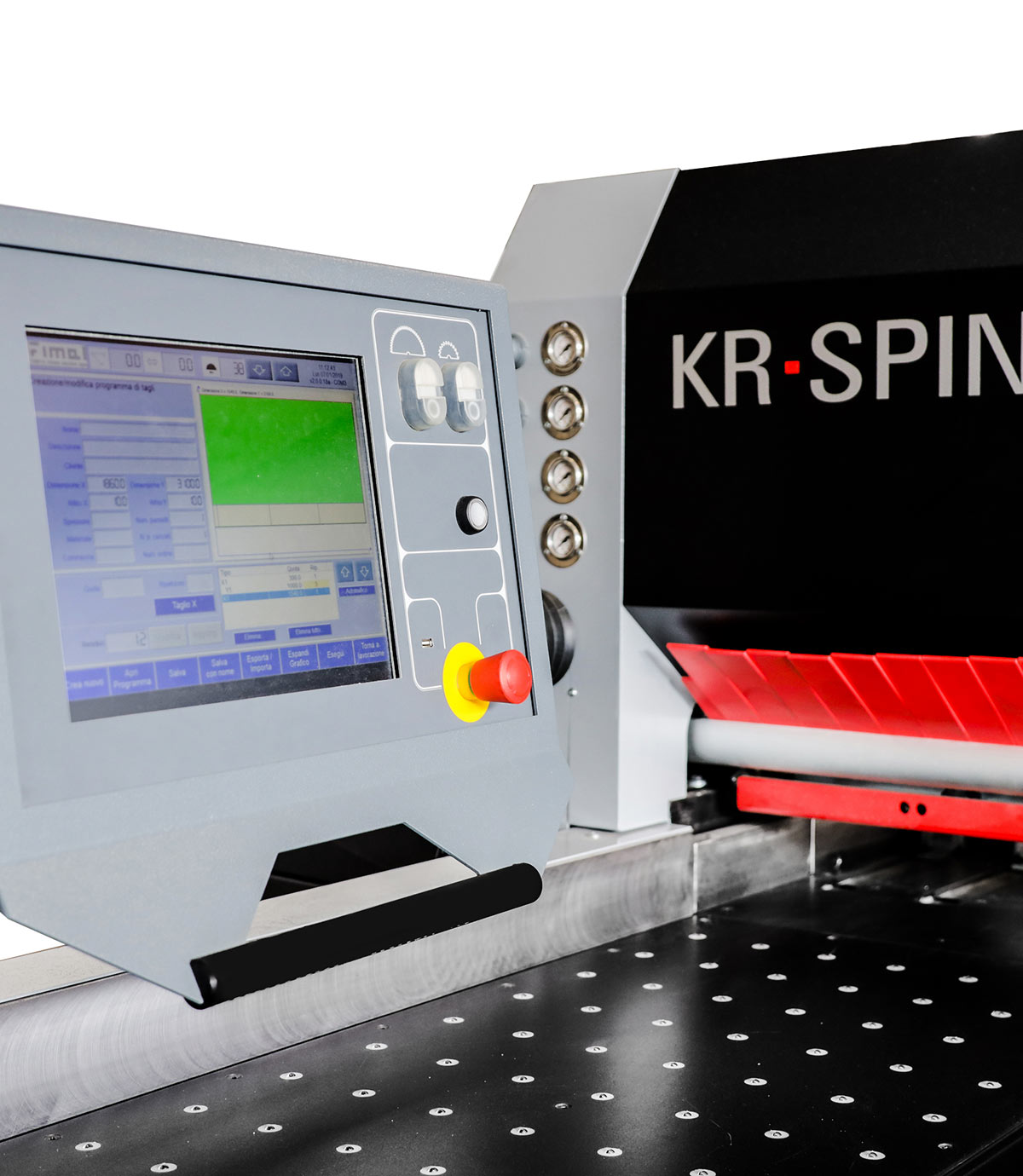

CONTROL UNIT AND LIFTING TABLES

The control unit with 15″ Touch Screen, adjustable by swinging, with Windows 10 IOT operative system guarantees fully automatic management of cutting schemes even if extremely complex thanks to great optimization of axis movements (sawblade carriage, pusher, side aligner).

If required, the machine can be equipped with two frontal lifting tables laterally adjustable and with synchronized raising movement, provided by linear motors. The tables allow loading and up&down movement of heavy panel stacks.

Controlled by the system and according to the cutting scheme they allow to process only the requested number of panels.

TECHNICAL DATA

ON REQUEST:

- Motorized frontal lifting tables

- Electronic sawblade height adjustment

- Software for free-tension precut

- Optimization on board

- Additional clamp