F.I.MA.L. redefines the standards of everyday life, starting with entry-level machines.

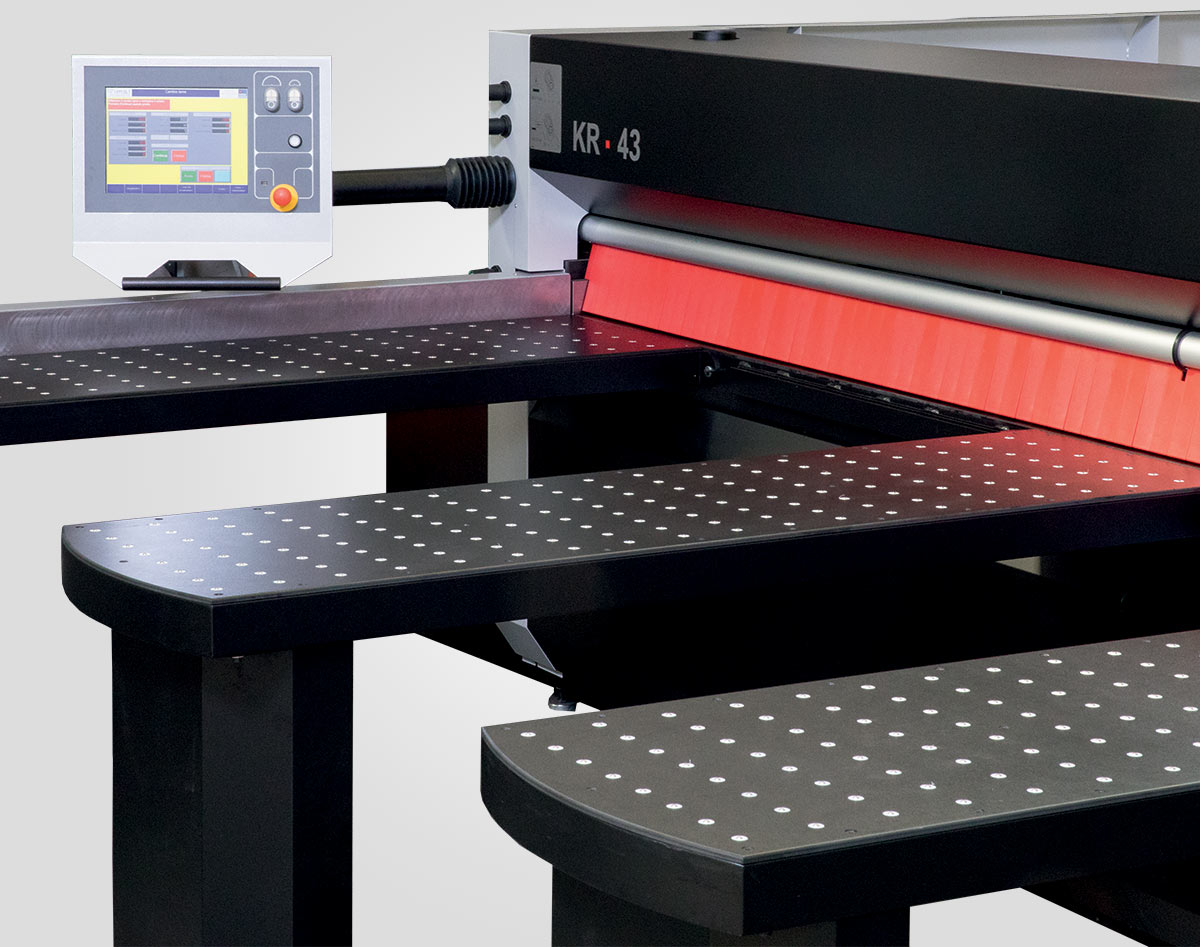

With the special KR32 and KR43 machines, woodworking has made a leap forward: high performance, maximum precision, high ergonomics, compact size and great ease of use.

Among woodworking machines, F.I.MA.L. electronic panel saws are an absolutely innovative solution for ordinary technologies.

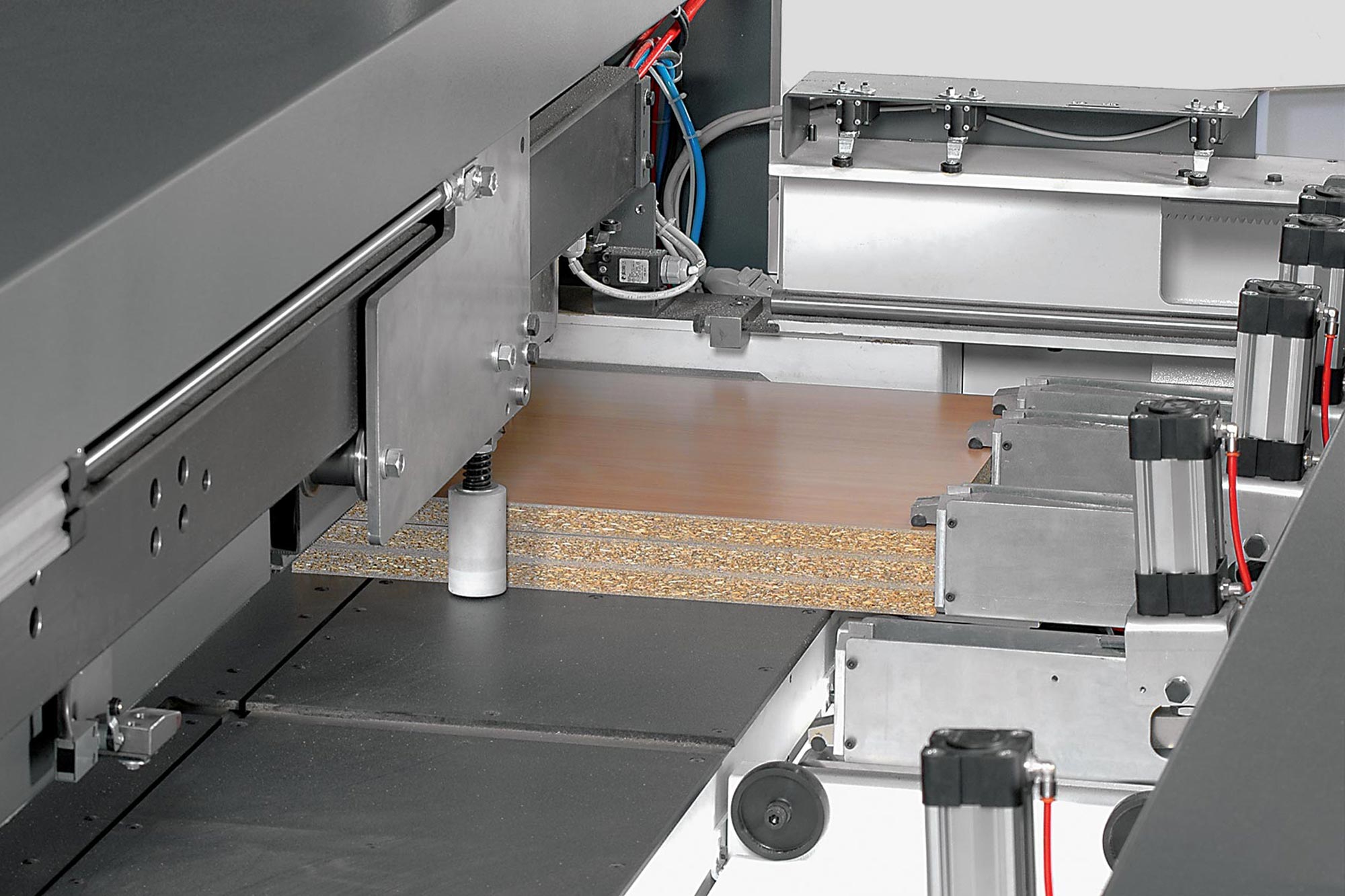

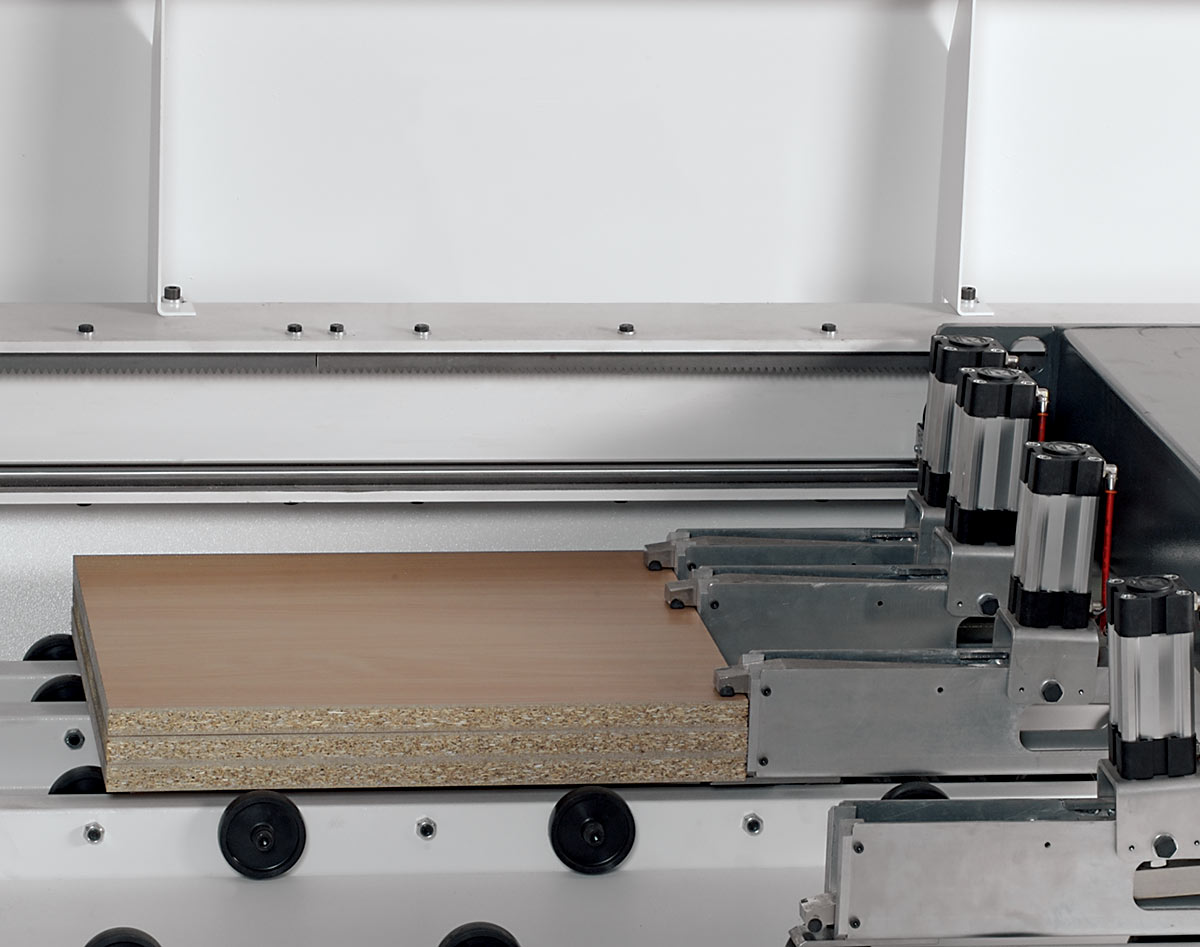

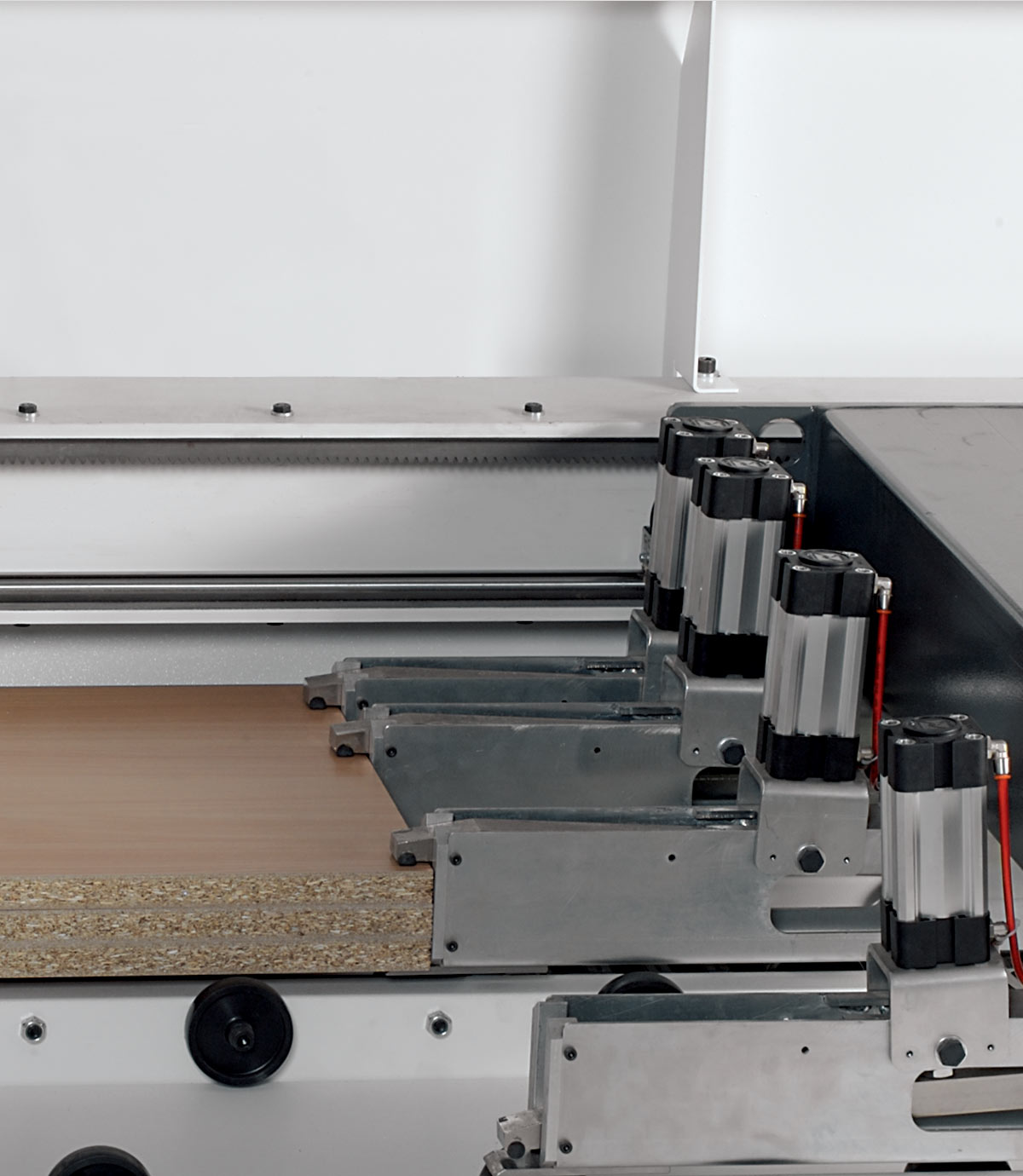

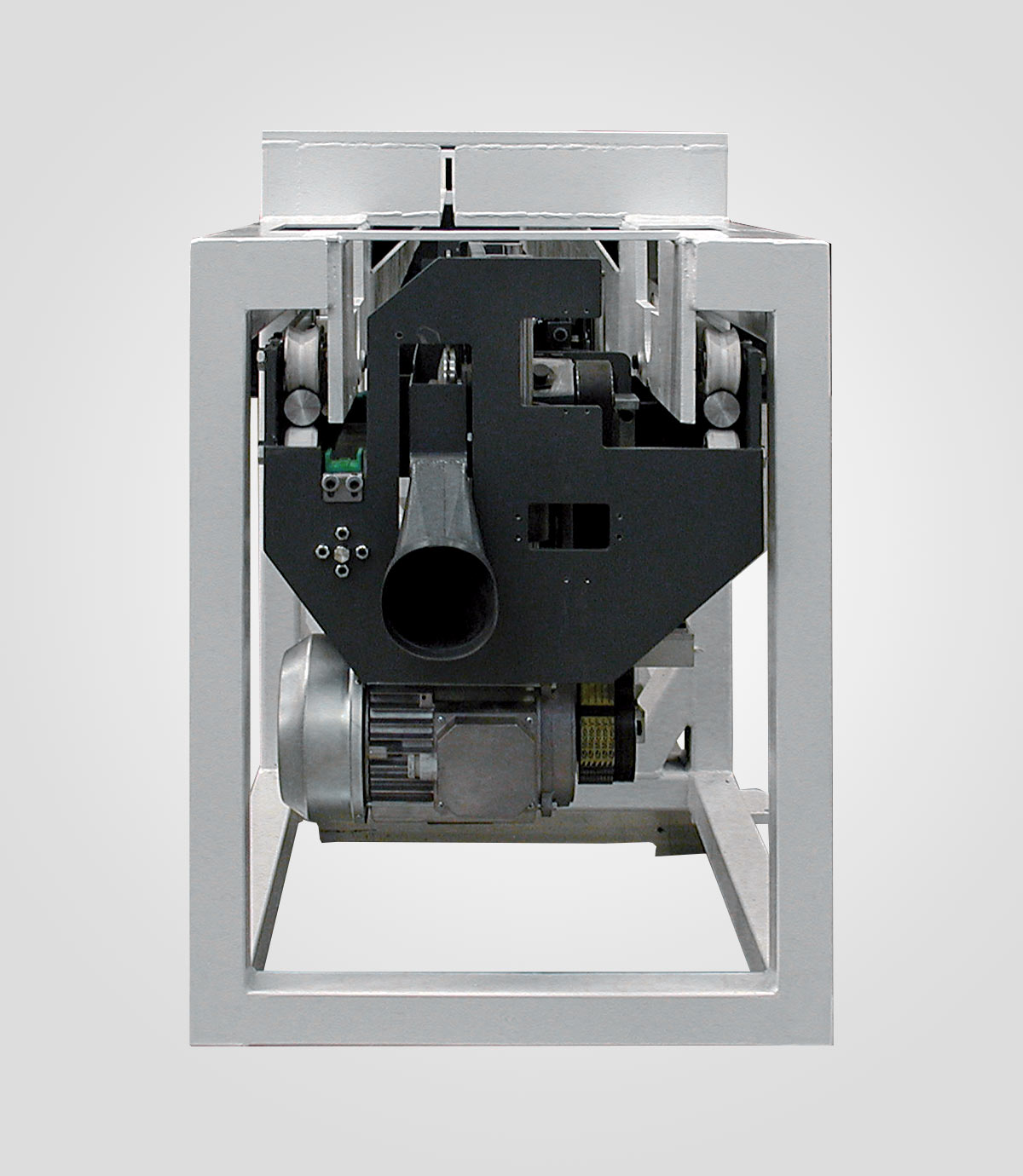

PUSHER CARRIAGE

Positioning the pusher carriage always takes place under the direct supervision of the machine control, which uses a magnetic band reading system to detect the position.

Suitably sized precision racks and pinions ensure accurate and parallel pusher movement.

The sliding table under the pusher carriage is equipped with independent idle rollers to avoid any scratching on panels with delicate surfaces.

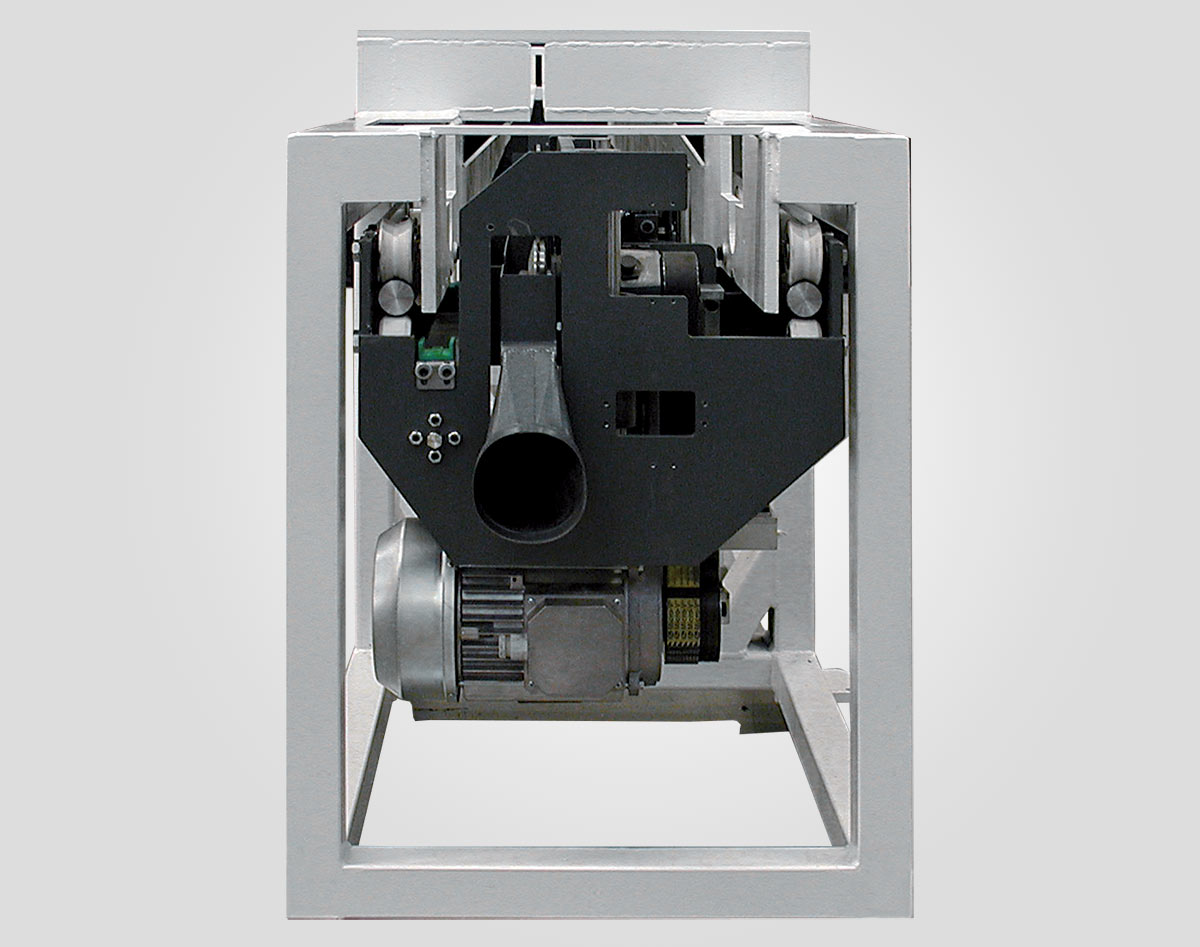

CUTTING LINE

The machine base comprises two elements, main base and secondary base, which are connected together by two side uprights.

This bridge structure is capable of counteracting the forces exerted by the pressure beam and the weight of the material to cut.

The main base also acts as the support for the saw carriage, which moves on two self-centring prismatic wheels along a hardened guideway located near the saw.

To further guarantee perfect contact with the gui deways, each prismatic wheel is combined with an opposed counterpressure wheel. The result is that any vibrations that could adversely affect the quality of the cut are eliminated.

NUMERICAL CONTROL

The numerical control guarantees the fully automatic management of the cutting patterns even if very complex, by optimizing the movement of the axes involved (pressure beam, saw carriage and side aligner).

An efficient diagnostic and troubleshooting program supplies complete messages regarding possible malfunctions, ensuring a quick solution to any problems.

In addition, controlled saw blade raising (optional) always ensures the correct saw blade protrusion from the pack being cut.

TECHNICAL DATA

PLUS:

- linear guides and controlled axes

- small machine dimensions

- high ergonomicity

- maximum precision

- uncompromising performance

ON REQUEST:

- Increased pusher travel

- Air cushion tables

- CNC control with touch screen

- Tables for angled cutting

- Inverter for varying saw speed

- Height adjustable saw raising

- Extra grippers

- Atomiser for saw blade lubrication

- Post-forming with electrical adjustment